Scientists from the University of Coimbra assess the environmental impact of different electric motor technologies

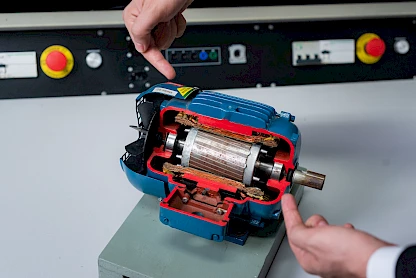

One of the main objectives of the project was to assess the environmental impact of the life cycle of different electric motor technologies by comparing squirrel cage induction motors (SCIM), which account for around 95% of motors used in industry, with IE3 efficiency (the minimum efficiency level allowed), and SynRM and PMSM motors, with IE5 efficiency.

A research team from the Faculty of Sciences and Technology of the University of Coimbra (FCTUC) is assessing the environmental impact of the life cycle of various electric motor technologies.

The results so far show that IE5 synchronous reluctance motors (SynRM), which have the highest standardised efficiency, are more efficient in operation, but have a higher environmental impact during manufacture.

"This is due to two main factors: the first is the use of more material to reduce losses, and the second is the use of specific materials, such as neodymium-iron-boron permanent magnets. The process of neodymium extraction and recovery has a high impact on both land and water," explains Danilo de Souza, a PhD student at the Institute of Energy and Environment (IEE) of the University of São Paulo (USP), Brazil, and an Erasmus student at the FCTUC Institute of Systems and Robotics (ISR).

According to the international student, "Although permanent magnet synchronous motors (PMSMs) are the most efficient, they have a higher environmental impact, particularly in their manufacture and disposal, due to the extraction of rare earth metals and recycling challenges".

One of the main objectives of the project was to assess the environmental impact of the life cycle of different electric motor technologies by comparing squirrel cage induction motors (SCIM), which account for around 95% of motors used in industry, with IE3 efficiency (the minimum efficiency level allowed), and SynRM and PMSM motors, with IE5 efficiency.

"We have tried to understand the environmental impact of these technologies from raw material extraction, through manufacturing, the most impactful phase - energy efficiency during use - to end-of-life, including disposal or recycling scenarios. Typically, only the use phase is analysed, while the others are neglected. This research will help to address this issue," he says.

In addition, by reinforcing efficiency and environmental sustainability as relevant criteria at each stage of the electric motor lifecycle, this project highlights the need to consider environmental impacts when selecting technologies for load drive mechanisms. "This is crucial for the promotion of energy efficient and sustainable products in the European market, in line with energy efficiency and greenhouse gas reduction targets," he concludes.

"The research was carried out with the active participation of FCTUC, under the supervision of Aníbal Traça de Almeida (ISR), and with the support of researchers João Fong (ISR) and Carlos Hernandez from the Centre for Industrial Ecology (CIE-FCTUC)".